Successful creation of propellant tanks requires proper sizing, proper analysis, and proper joint design. This post we will cover various joints in metallic tanks and then we will complete the tank post series in the next post with a case study.

There are 2 main ways to make joint on propellant tanks: Bolted or Welded. Other methods exist such as brazing, epoxy, rivets, etc., but 99% of the time either welding or bolting are used.

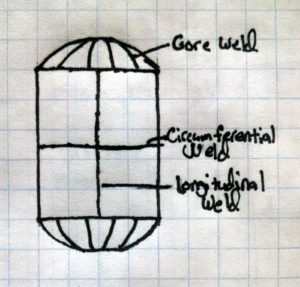

Welding is generally used to join the major structural pieces of propellant tanks with the main welds longitudinal welds to form a cylinder from a rolled segment, circumferential welds to join cylindrical segments and endcaps, and, in the case of very large tanks, gore welds to form endcaps. Small tanks can avoid some of these welds, but sheet stock is usually limited to 144″ x 72″ so anything larger will require many more welds.

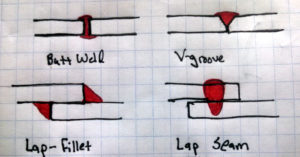

Most welds on propellant tanks are either butt welds or lap welds as shown on the picture below.

It is almost always desired to have thicker material at a weld to minimize any stress associated with weld discontinuity and lower strength due to heat affected zones. As a rule, try to minimize the number of welds and keep welds away from high stress areas; for instance, by making the dome of the tank extend a half tank diameter into the body before welding on the cylindrical section. This may cost more to make, but it should also have better performance. In addition, you can make tank cylindrical segments from spin forging, eliminating the high stress longitudinal weld.

One final note on welding is that most materials lose strength when welded so either account for that in thicker parts, or plan on post weld heat treatment. Heat treatments need to have minimal thermal shock as the large, thin structures of a tank are prone to buckling or deforming under high thermal loads such as quenching. For most heat treatable aluminums, this means only aging after welding, not a full solution heat treat.

The other option for connections are bolts with seals. Most propellant tanks, even composite or large welded structures, have bolted port holes or man hole covers. A simple method, or at least comparatively simple, of constructing a propellant tank is a seamless tube with flat caps at both ends.

The first part of the system is the bolts. These are ideally the same material as the base structure, or at least the same CTE (Coefficient of Thermal Expansion), to ensure changes in temperature do not over-stress or unload the joints. The two main gotchas on the system are you need to pre-stress the bolts to a higher level than they are stressed in the pressure load case to minimize cyclical loading and bolt pull out strength is a function of the base material or the thread material, whichever is weaker. So if you are using 7075-T6 bolts on a 5052 H32 tank, you need to calculate the stress assuming the thread will rip out of the 5052.

Part number two is the seal. For a fluid between -65F and 200F, just use an o-ring. Most of the time either Viton or silicone will work, and Parker has a great o-ring handbook for design guides. Outside of this temperature range, the easiest option is a Teflon gasket or sealing ring, and the best option is a metal o-ring. Size the Teflon sealing ring just like an o-ring but make the Teflon a square cross section instead of a circle for easy fabrication. It will smoosh out in use and is usually reusable until you take the seal out of the groove. They are cheap and easy. A metal o-ring or c-ring, otherwise known as a metal energized seal, will work very well on a flat and good surface finish surface. They can work down to liquid hydrogen temperatures and up to ~1200F, but they are expensive and long lead items and, if you scratch the sealing surface, that part is scrap. So only use metal seals if it is colder than LN2 or hotter than 400F.

I hope this was informative, and we’ll do a case study for the Project Earendel tank next week.

Medicines information sheet. Short-Term Effects.

can i buy generic lyrica without a prescription in USA

Actual information about medicine. Get now.

Pills prescribing information. Effects of Drug Abuse.

can i get cheap pregabalin without rx in the USA

Actual information about drug. Read information now.

cialis instructions cialis daily cialis tablet

viagra vs cialis vs levitra canadian pharmacy ezzz cialis cialis coupon cvs

when to take cialis for best results tadalafil from india reviews viagra vs cialis reddit

how to write a thesis for an informative essay cheap essay writing services how to write essay question

cialis vs levitra tadalafil generic cialis 5 mg

essay about the importance of community service write good essays essay about writing experience

help me write my college essay writing college admission essays how to write an essay on a painting

cheap viagra viagra soft buy sildenafil

definition essay on customer service cheapest essay writing service “essay writing service write my essay custom essay pay for essay”

viagra pranks viagra foods sildenafil generic

sildenafil pronunciation sildenafil prescription generic viagra over the counter

viagra sildenafil order viagra online sildenafil online canada

cialis dosing generic tadalafil cheap cialis canada

walk me through your resume certified professional resume writers resume buzz words

investment banking resume resume services online resume parser

cover letter writing top resume reviews nursing resumes

what doe cialis look like generic cialis canada cialis price per pill

photographer resume url marissa mayer resume

sildenafil citrate 20 mg viagra prescription viagra no prescription

viagra connect sildenafil 100mg sildenafil price walmart

where to buy sildenafil instant natural viagra sildenafil pronounce

cialis canadian pharmacy ezzz cialis vs. viagra recreational use how long does cialis take to kick in

cialis without a doctor prescription canada cialis 5mg best price 20mg cialis

sildenafil citrate 100mg viagra over the counter natural viagra

cialis for sale viagra and cialis together is cialis safe

generic cialis 2018 tadalafil research chemical cost of cialis without insurance

предприятия россии база данных

online essay grammar service custom thesis help compare and contrast essay customer service