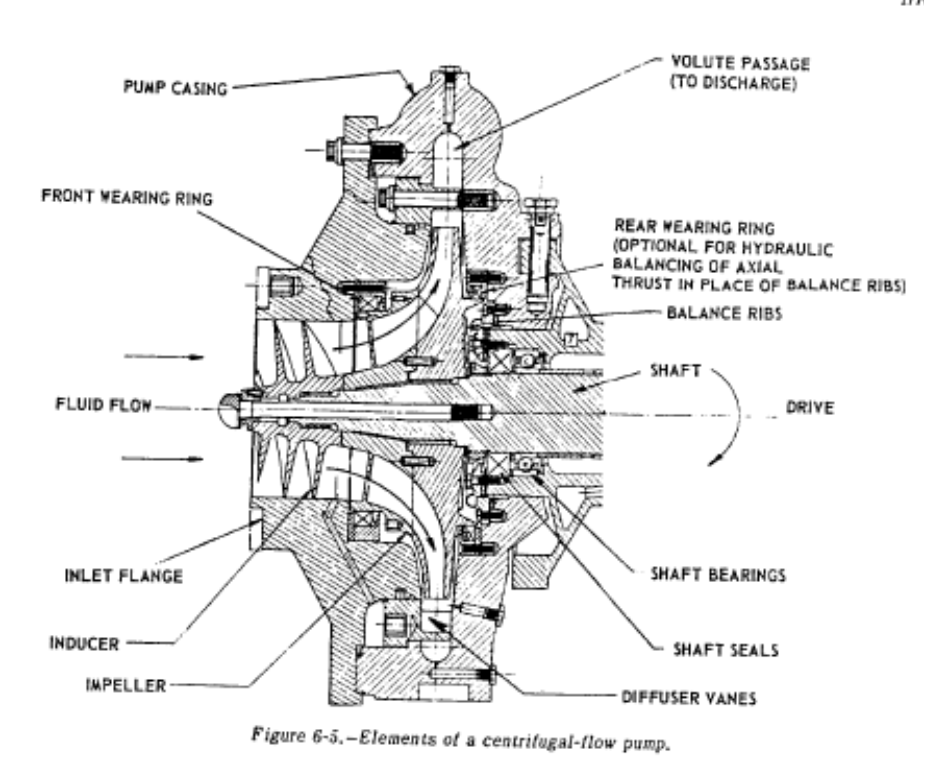

For the sake of this discussion, we will only consider centrifugal pumps – but if you are doing rockets and not using hydrogen, that is a good assumption. The pump on a rocket is broken up into 3 main parts: the inducer, the impeller, and the volute. The inducer is a low pressure rise pump that limits cavitation in the impeller; it is only necessary for high specific speed pumps, which is most of rocketry. The impeller is the main pumping element and is effectively a paddle wheel that takes slow moving fluid from the core and ejects it at high speed from its sides. The volute takes the high speed fluid and slows it down, converting the high speed to high pressure. All told, they make up a rocket pump, but we will just go over the basic sizing of the impeller and not worry about fun things like velocity triangles today.

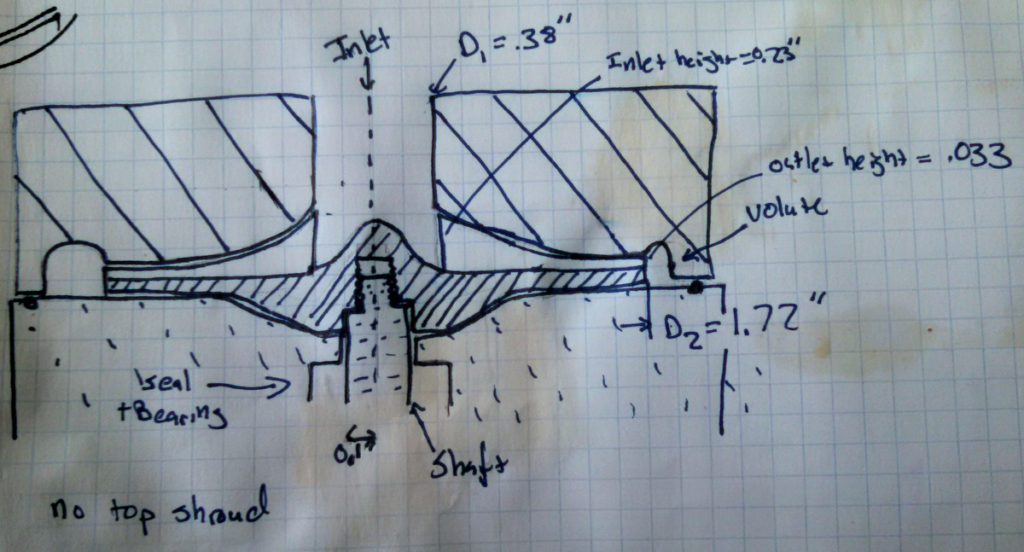

Once you have done all of the basic sizing that we talked about last week, you have the basic properties of the pump system but no sizes. If you want to do a detailed pump sizing, I would recommend NASA SP-125 and SP-8109 as it is a bit more complicated than a blog post. But, today, let’s get you the two biggest pieces of information you need: outlet diameter and outlet height. These are useful to determine the mass and manufacturability of the pump, as outlet height is usually the smallest geometry and diameter of the impeller and, thus, the volute determines most of the mass properties for a pump.

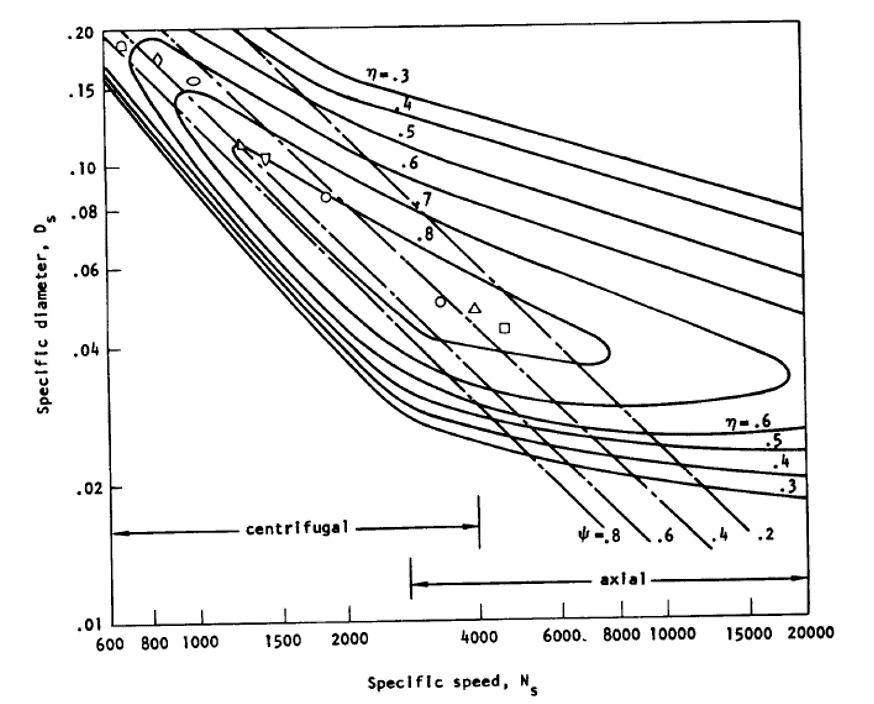

The process for exit diameter is iterative and consists of the following equations (everything in ft, GPM, ft/s, and RPM):

Head_Coefficient = gravity * Head_Rise / (Tip_Velocity)^2

Specific_Diameter = Tip_Diameter * Head_Rise^0.25 / Flowrate^0.5

Tip_Diameter = Tip_Velocity / (pi * RPM)

Then use the plot below.

So now iterate on that for a bit, and we have the outlet diameter.

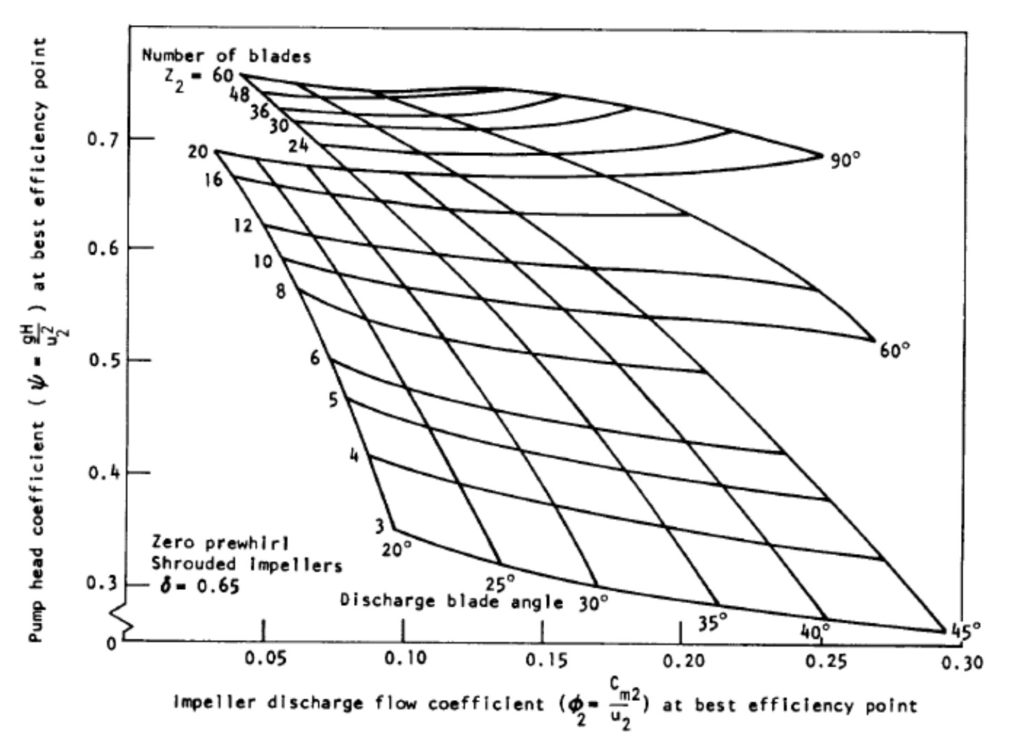

To find the exit height the equation is:

Exit_Height (in) = Flow_Rate(GPM) / (3.12 * pi * exit_diameter(in) * exit_radial_velocity(ft/s) * contraction_factor)

where the contraction factor is usually estimated as 0.9 and the radial velocity can be estimated by:

exit_radial_velocity = flow coefficient * tip_velocity

Flow coefficient is usually between 0.01 and 0.15 and can be found on the plow below.

I hope this has all been useful in determining how to size a impeller; obviously the final design is more complicated with flow angles, but these basics should point you in the correct direction.

Hello, just wanted to tell you, I liked this blog

post. It was funny. Keep on posting!

Unquestionably believe that which you stated.

Your favorite reason seemed to be on the web the simplest thing

to be aware of. I say to you, I certainly get annoyed while people think about

worries that they just don’t know about. You managed to hit the nail upon the top and defined out the whole thing without having side-effects , people can take a

signal. Will probably be back to get more. Thanks

I am in fact grateful to the holder of this site who has

shared this fantastic paragraph at here.

you’re in reality a good webmaster. The web site loading pace is incredible.

It kind of feels that you are doing any distinctive trick.

Also, The contents are masterwork. you have done a great

job in this topic!

Hello just wanted to give you a brief heads up and let you know

a few of the pictures aren’t loading properly. I’m not

sure why but I think its a linking issue. I’ve tried it in two different

internet browsers and both show the same

outcome.

It’s an amazing paragraph in support of all the web viewers; they will get advantage from it I am sure.

We’re a group of volunteers and starting a brand new

scheme in our community. Your site provided us with helpful information to work on. You

have performed an impressive job and our whole neighborhood

will probably be thankful to you.

Please let me know if you’re looking for a article writer for your weblog.

You have some really good articles and I think I would

be a good asset. If you ever want to take some of the load off, I’d love to write some articles for your blog in exchange

for a link back to mine. Please send me an e-mail if interested.

Many thanks!

Hi! I’m at work browsing your blog from my new iphone 3gs!

Just wanted to say I love reading your blog and look forward

to all your posts! Keep up the great work!

Medicine information for patients. Generic Name.

where can i get cheap pregabalin without insurance in USA

Actual what you want to know about meds. Read information here.

is there a generic cialis available in the us buy cialis cialis viagra online

is there a generic for cialis cialis canadian pharmacy ezzz coupon for cialis

how to write an argumentative analysis essay custom essay writing service write an argumentative persuasive essay

college essay writing essay writing service narrative essay writing writing reflective essays

herbal viagra super viagra sildenafil 100mg price walmart

generic viagra walmart canadian pharmacy ezzz viagra sildenafil online

warehouse resume work experience resume cv versus resume

otc cialis cialis and bph cialis india

combination resume best resume writing services reviews references page for resume

roman viagra herbal viagra sildenafil 100mg price walmart

viagra and cialis tadalafil tablets 20 mg cialis vs. viagra

viagra pills viagra online over the counter viagra cvs

purchasing cialis cialis reddit does cialis keep you hard after coming

I enjoyed this. Thank you.

food production in commercial service operations essay cheap essay writer talking about community service and volunteer work in essay